Technology

- Home

- TECHNOLOGY

Screen printing

Screen printing is a traditional and very popular printing method.

It uses a screen with a design on it to push ink through openings in the screen and transfer it to the garment. This method is suitable for high-volume printing because it costs less to print on each garment and produces rich, durable graphics. However, since each color requires a separate screen, complex, multi-color designs will be more time-consuming and laborious in the initial production.

Direct-to-Garment (DTG)

Digital direct printing uses technology similar to inkjet printers to print designs directly on clothes.

This method is ideal for small batches or designs that require a high degree of detail and multiple colors, as it does not require making a screen. DTG printing can accurately present complex patterns and gradient colors, and is suitable for personalized or small-volume customization needs. However, relatively speaking, the cost of a single piece will be higher, and the durability of printing may not be as good as screen printing.

Heat Transfer

Heat Transfer is a method of transferring printed patterns from transfer paper to clothes through high temperature.

This technique is suitable for detailed, multi-color patterns, especially when you want to print a small amount in a short period of time. The benefit of heat transfer printing is that it works well on different fabric materials, but the disadvantage is that the pattern may crack or peel over time.

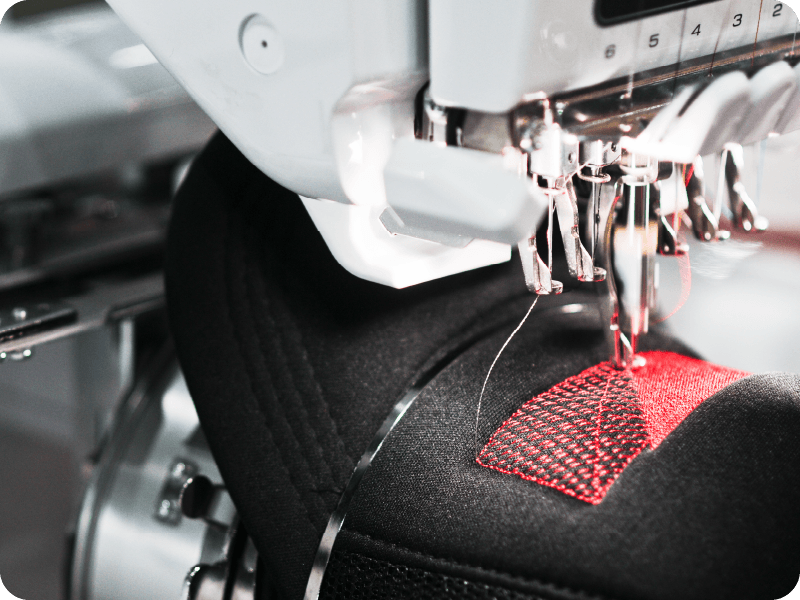

Embroidery

Embroidery uses a sewing machine to embroider threads into designs and weave them directly onto clothes.

This approach gives a premium and three-dimensional feel, perfect for business uniforms, team apparel or brand logos, etc. Embroidery is very durable and not easy to fade or be damaged, but it is not suitable for small and complex patterns, and compared to printing technology, the unit price of embroidery will be higher, especially for multi-color designs.